Produce a rug

We are a professional rug manufacturer since 2008. Today we want to introduce an overview of the steps involved in producing a rug:

1. Design

Design Creation: The first step is to create a design for the rug. We hire rug designers with 14 years of design experience.Every pattern is carefully designed by the designer. Some are inspired by natural scenery, some are inspired by historical allusions, and some are inspired by daily life.

2. Material Selection and Preparation

Yarn Selection: The yarn used for our rugs is typically synthetic: polyester. The choice of yarn affects the rug's durability, appearance, and feel. Then, the yarn is dyed in various colors according to the design specifications.

3. Weaving Process

Weaving: In machine-woven rugs, the loom interlaces the warp and weft threads (the horizontal threads) to create the rug. This process can produce flatweave rugs.

4. Composite Layering

We will composite the anti slip backing and fabric, then rugs are ready to be printed.

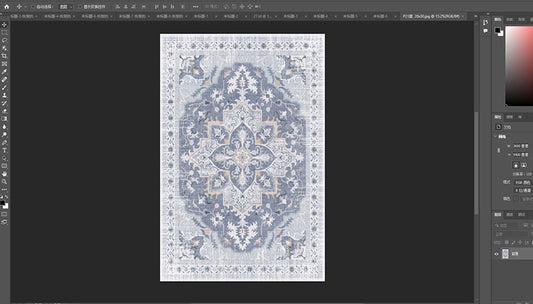

5.Digital Printing

This is the most common method for printing rugs due to its precision and ability to produce detailed designs.

6. Finishing Processes

Edge Finishing: The edges of the rug are finished to prevent fraying. This can involve binding, serging, or hemming the edges.

7. Quality Control

Inspection: The finished rug undergoes a thorough inspection to check for any defects, such as uneven pile height, color discrepancies, or loose threads. Any issues are corrected before the rug moves on to the next stage.